Call Us:-+886282619777

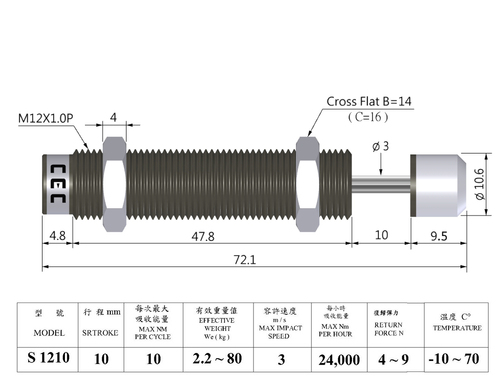

S 1210 Shock Absorber

15.9 USD ($)/Piece

Product Details:

- Application Industrial automation, machinery, robotics

- Sealing Type Double Seal

- Efficiency Over 95%

- Mounting Type Threaded

- Power Source Mechanical

- Operating Pressure Up to 10 Bar

- Accessories Lock nut, dust cap

- Click to View more

X

S 1210 Shock Absorber Price And Quantity

- 10 Piece

- 15.9 USD ($)/Piece

- 15.90 - 21.60 USD ($)/Piece

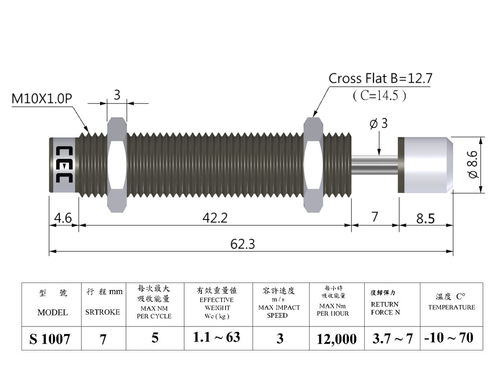

S 1210 Shock Absorber Product Specifications

- Lock nut, dust cap

- Up to 10 Bar

- Direct Mount

- Piston Cylinder

- Over 95%

- Threaded

- Hydraulic Shock Absorber

- Stainless Steel

- Industrial automation, machinery, robotics

- Double Seal

- Mechanical

S 1210 Shock Absorber Trade Information

- 10000-3000 Piece Per Month

- 30 Days

Product Description

We are offering a perfect selection of S 1210 Shock Absorbers. They are known for high strength and excellent shock absorbing capability. Find their use in industrial equipment and machines, these absorbers are known for their chrome finish and ruggedness. The offered absorbers are manufactured with excellent quality raw materials to ensure the long lasting corrosion free effect and high strength keeping in mind industrial quality set industry norms. To meet the diversified need of our clients, we offer these S 1210 Shock Absorbers in various specifications at industry leading prices.

Features:

- Control the flow of oil through an internal piston.

- Makes use of valves to absorb excess energy from the springs.

- Serve the purpose of limiting excessive suspension movement.

Advanced Motion Control Solution

Designed for modern industrial environments, the S 1210 Shock Absorber excels in absorbing kinetic energy effectively across various automated and robotic systems. With hydraulic damping and a robust stainless steel body, it minimizes vibration, reduces machine wear, and promotes operational longevity. Its compact size and specialized mounting facilitate seamless integration into restricted spaces.

Durability Meets Efficiency

Engineered with a high-grade stainless steel exterior and double-seal system, the S 1210 stands up to rigorous operational demands. The efficient hydraulic mechanism ensures steady performance at pressures up to 10 Bar, while the low noise output supports a quieter, safer working environment. Accessories like the lock nut and dust cap further enhance functionality and protection.

FAQs of S 1210 Shock Absorber:

Q: How is the S 1210 Shock Absorber installed in industrial machinery?

A: The S 1210 Shock Absorber is designed for easy integration and features a threaded mounting type. It can be directly mounted to machinery, using the included lock nut for secure positioning and the dust cap for additional protection against contaminants.Q: What are the typical applications for this hydraulic shock absorber?

A: This shock absorber is ideally suited for industrial automation, machinery, and robotics where precise damping is needed. Its compact size and efficient energy absorption make it effective in areas with limited space or high-speed motion scenarios.Q: When should I use a hydraulic shock absorber with a 10 mm stroke and 10 Nm/cycle energy rating?

A: Choose this model when your application requires consistent energy absorption up to 10 Nm per cycle and stroke limitations of 10 mm, especially in environments demanding low noise operation and high efficiency.Q: Where does the S 1210 Shock Absorber originate and how is it distributed?

A: The S 1210 is manufactured, supplied, and distributed from Taiwan. Global distribution includes exporters, importers, and traders, ensuring broad accessibility for industrial clients worldwide.Q: What process ensures the S 1210 maintains high efficiency and low noise during operation?

A: The device utilizes hydraulic oil as the damping medium and incorporates a piston cylinder structure with a double sealing system. This combination effectively absorbs kinetic energy and minimizes operational noise, while maintaining mechanical efficiency over 95%.Q: How do the lock nut and dust cap accessories benefit the installation?

A: The supplied lock nut secures the shock absorber in place, preventing loosening from vibration. The dust cap protects the assembly from dust and debris, extending operational life and maintaining performance integrity.Q: What are the primary benefits of integrating the S 1210 Shock Absorber into robotics and automation systems?

A: By providing reliable energy absorption and smooth motion damping, the S 1210 improves machine safety, reduces maintenance needs, minimizes operational noise, and enhances the longevity of mechanical components in demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email