SCD 2030 Shock Absorber

Product Details:

- Power Source Mechanical

- Operating Pressure Max 8 kg/cm

- Accessories Lock Nut, Adjustment Tool

- Sealing Type NBR Rubber Seal

- Features Corrosion Resistant, Adjustable Absorbing Range, Compact Design

- Temperature Range -10C to +70C

- Connectivity Type Direct Mechanical Interface

- Click to View more

SCD 2030 Shock Absorber Price And Quantity

- 40.60 - 55.40 USD ($)/Piece

- 40.6 USD ($)/Piece

- 1 Piece

SCD 2030 Shock Absorber Product Specifications

- Threaded (M16 x 1) Mount

- Hydraulic Shock Absorber

- 20-30 kgf

- High Damping Efficiency

- Lock Nut, Adjustment Tool

- Adjustable

- Single Tube, Piston-Cylinder

- -10C to +70C

- NBR Rubber Seal

- Corrosion Resistant, Adjustable Absorbing Range, Compact Design

- Mechanical

- Max 8 kg/cm

- Industrial Automation, Robotics, Machinery Damping

- Direct Mechanical Interface

- High Strength Carbon Steel

SCD 2030 Shock Absorber Trade Information

- 3000 Piece Per Month

- 30 Days

Product Description

SCD 2030 Shock Absorber

We are backed by skilled and adept professionals who always focus on manufacturing and exporting a remarkable range of SCD Series Shock Absorber. Our shock absorbers are installed in machines and systems to control the linear movement and to increase the functionality. We employ advance machines and quality approved materials to design SCD 2030 Shock Absorbers, in accordance with industry set norms and standards.

Features:

- Mounted easily in confined spaces owing to its compact design

- High energy absorption, corrosion resistance and less maintenance are some of its salient attributes

- Can also be customized as per the clients requirements

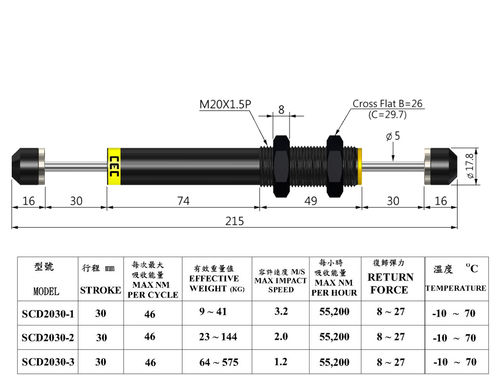

Technical specification:

- M20X1.5P

- Cross Flat B=26 (C=29.7)

|

Model |

Stroke (mm) |

Max NM Per Cycle (mm) |

Effective weight we (kg) |

Max Impact Speed |

Max NM Per Hour |

Return Force N |

C Temperature |

|

SCD 2030-1 |

30 |

46 |

9- 41 |

3.2 |

55,200 |

8 - 27 |

-10 -70 |

|

SCD 2030-2 |

30 |

46 |

23 - 144 |

2.0 |

55,200 |

8 - 27 |

-10 - 70 |

|

SCD 2030-3 |

30 |

46 |

64 -575 |

1.2 |

55,200 |

8 - 27 |

-10 - 70 |

Advanced Performance for Industrial Precision

With a maximum energy absorption of 35 Nm per cycle, the SCD 2030 delivers consistent damping in fast-paced environments, supporting up to 90 cycles per minute. Its mechanical power source and threaded M16 x 1 mounting type allow easy and secure installation in machinery. The integrated return spring enhances cycle time, and high-efficiency damping preserves equipment longevity.

Durable and Environmentally Resistant Engineering

The shock absorbers high-strength carbon steel structure, finished in black oxide, offers superior resistance to corrosion and harsh conditions. NBR rubber seals provide reliable environmental protection against dust and oil. Its RoHS-compliant build further ensures environmental responsibility, making it an excellent choice for demanding workspaces.

FAQs of SCD 2030 Shock Absorber:

Q: How is the SCD 2030 Shock Absorber installed and connected?

A: The SCD 2030 is mounted using its threaded M16 x 1 (male thread) fitting, facilitating direct mechanical interface with your machinery. Lock nuts and an adjustment tool are provided to ensure a secure and proper installation.Q: What applications are suitable for this shock absorber model?

A: It is ideal for industrial automation, robotics, and damping of machinery, particularly where compact design, efficient noise reduction, and robust energy absorption are essential, such as in factory lines or automated equipment.Q: When should the speed adjustment feature be used?

A: The adjustable speed capability should be utilized when varying impact velocities or changing operational requirements occur, allowing for fine-tuning of the damping effect to match specific process conditions.Q: Where can the SCD 2030 Shock Absorber be deployed for maximum benefit?

A: It is most beneficial in environments requiring efficient vibration and impact managementsuch as automated production lines, robotic arms, or sensitive machinerywhere space is limited, and environmental factors like dust and oil may be present.Q: What process should be followed for shock absorber maintenance?

A: Routine visual inspection for signs of surface corrosion or seal wear is recommended. The devices dust and oil-resistant structure minimizes maintenance, but occasional cleaning of the external surface and checking end fittings assures longevity.Q: How does the integrated return spring enhance performance?

A: The return spring rapidly resets the piston after each absorption cycle, enabling high operational frequencies (up to 90 cycles/minute) and supporting continuous, uninterrupted industrial processes.Q: What are the key benefits of utilizing this shock absorber in machinery?

A: Primary benefits include high damping efficiency, reduced noise ( 18 dB), longevity due to corrosion-resistant and high-strength materials, and the ability to withstand demanding environments while maintaining compactness and energy absorption capacity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+