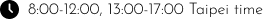

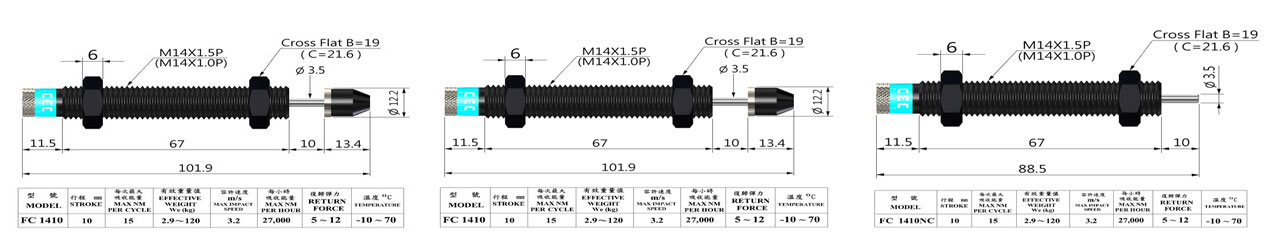

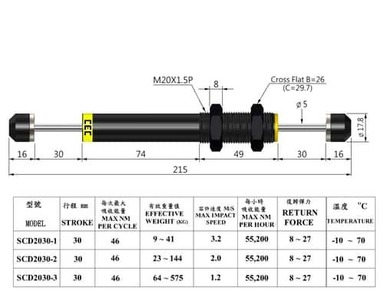

Hydraulic Shock Absorbers are the hydraulic devices, which have been peculiarly designed to damp as well as absorb the shock impulses. These help you to make your production more efficient with fast processes, which also ensure safety and sustainability. These devices damp the shock impulses by converting the kinetic energy into another kind of energy.